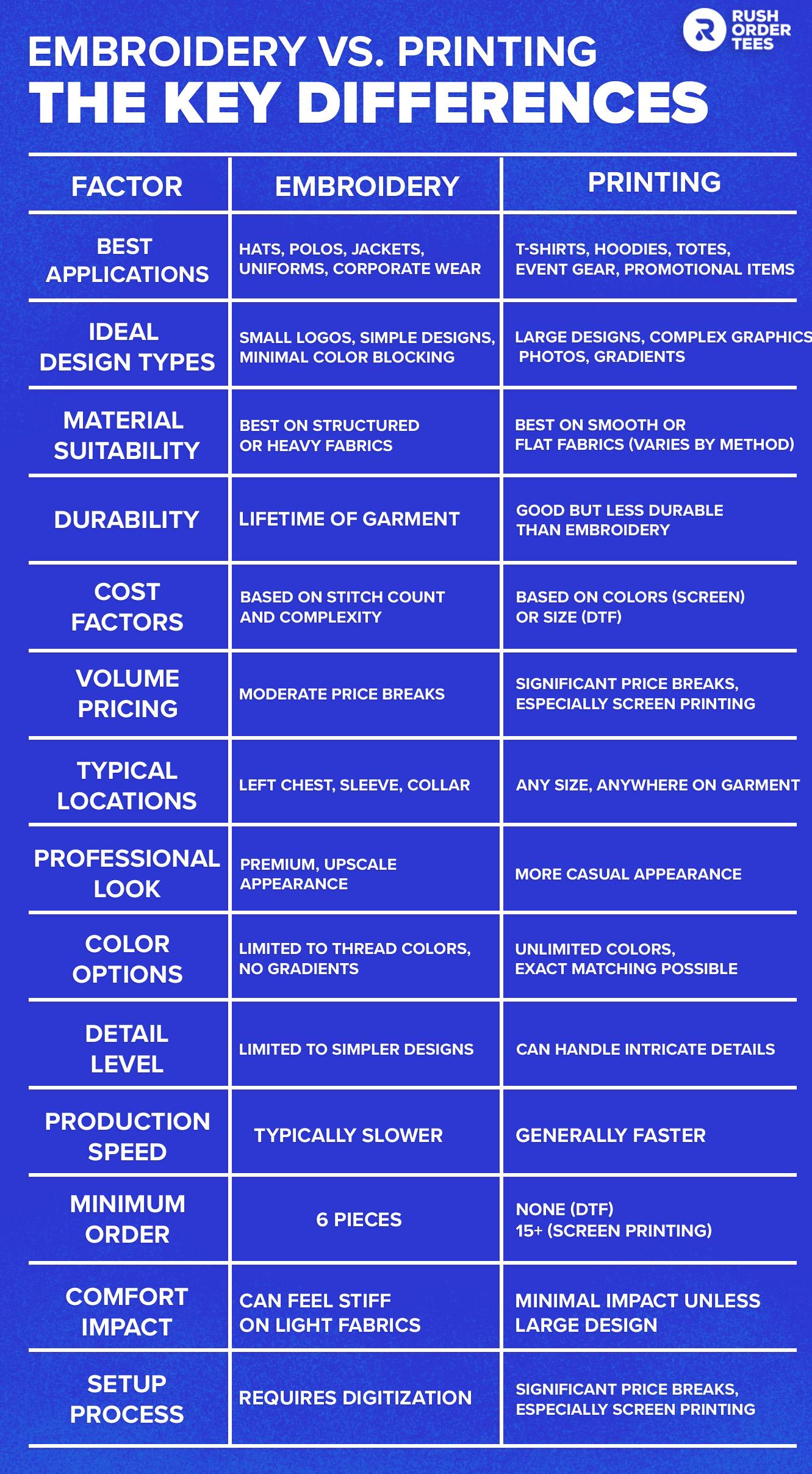

Embroidery and printing stand as the two primary decoration methods in the custom apparel universe, and after 20+ years of crafting custom gear, we've mastered both. While each technique delivers stunning results, they serve different purposes and work better with specific designs, fabrics, and use cases.

This guide breaks down the key differences between embroidery and printing, walking you through each method's pros, cons, and ideal applications. Whether outfitting a corporate team, creating merch, or designing uniforms, understanding these options helps you make the right choice for your project. Here's a quick crash course on how these two methods compare.

What Is Embroidery?

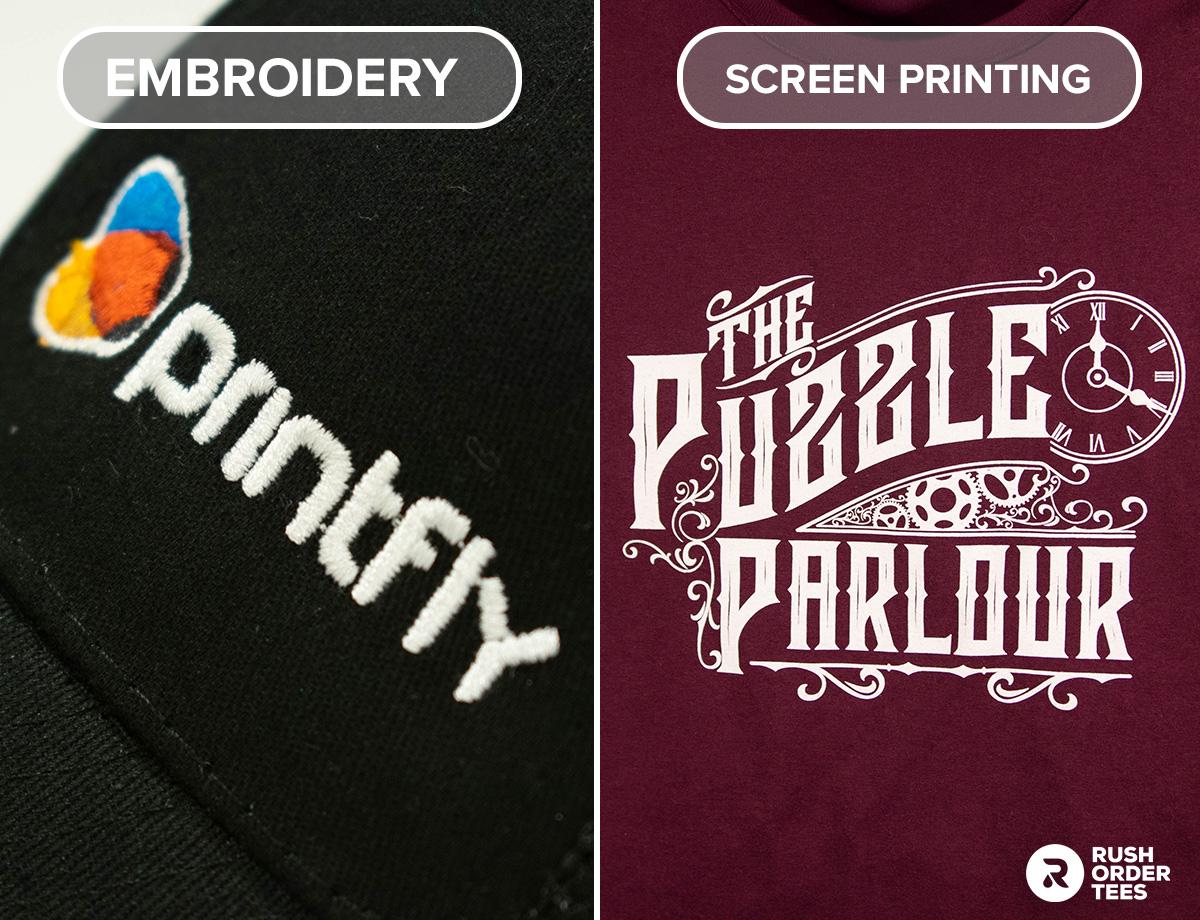

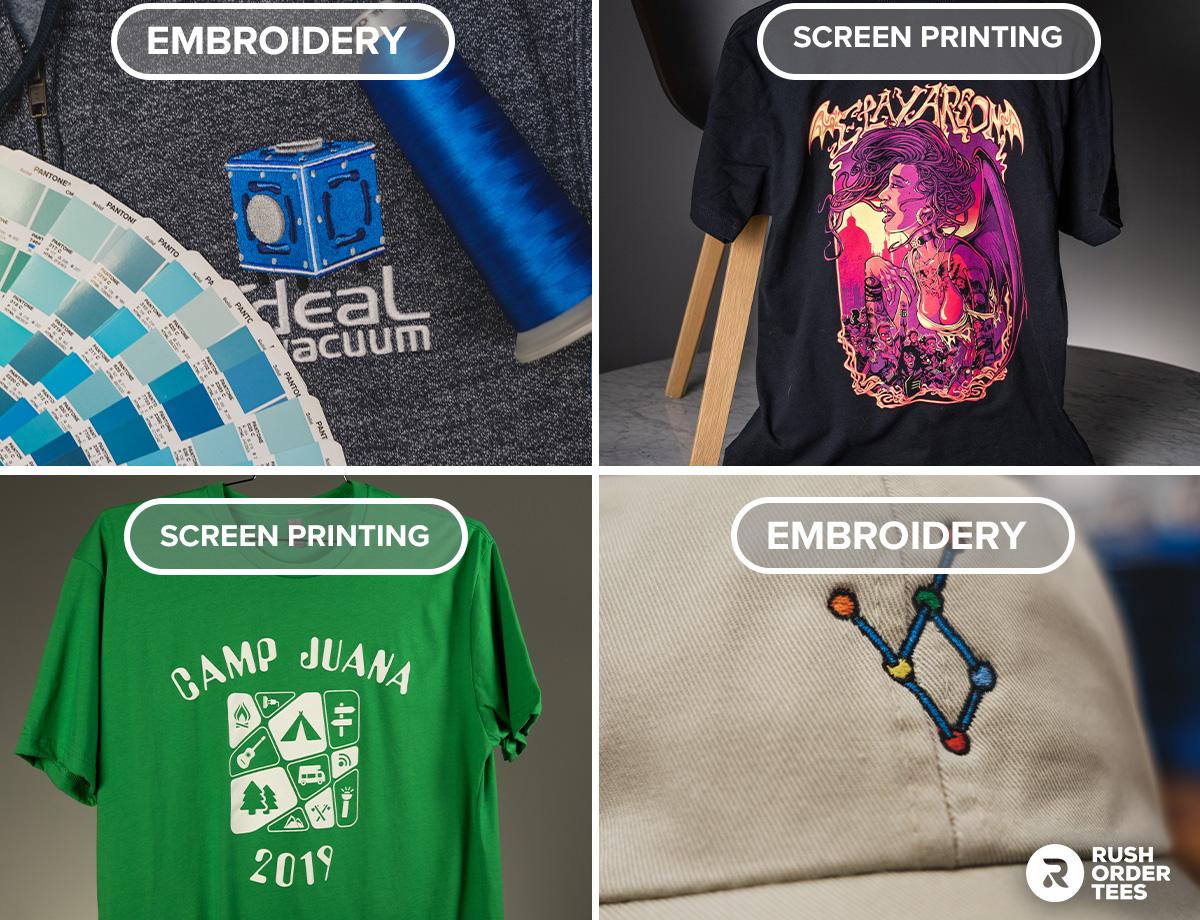

Embroidery recreates designs through precision-stitched thread, transforming logos and artwork into textured, three-dimensional decorations. While it's one of the oldest garment decoration methods, modern embroidery combines traditional craftsmanship with high-tech machinery capable of producing intricate designs at remarkable speeds. This technique stands out for its professional appearance and unmatched durability—your embroidered design will typically outlast the garment itself.

Embroidery excels on structured garments and thicker fabrics, making it ideal for hats, polos, jackets, sweatshirts, and workwear. Most embroidered designs appear on the left chest, though smaller logos can add subtle branding to sleeves, collars, or the upper back. You'll often see embroidery combined with printing on the same garment, like a small embroidered logo on the chest with a larger printed design on the back. This decoration method particularly shines in professional and corporate environments where that elevated, premium look matters.

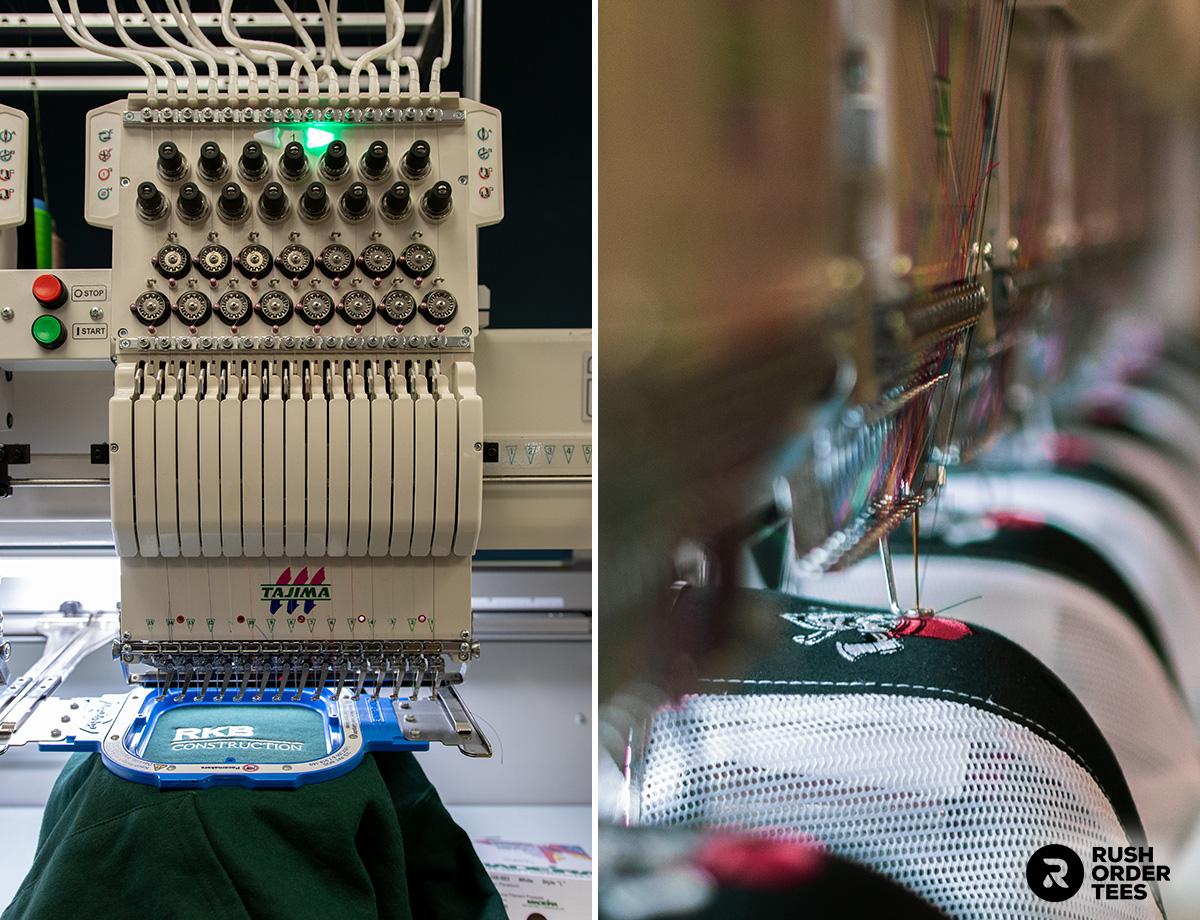

Embroidery process:

- Artwork is optimized, simplifying complex elements to work within embroidery's limitations.

- The design is digitized: a crucial step to map out the number of stitches and thread patterns.

- This digitized file becomes a program that guides our Tajima embroidery machines.

- Garments are loaded onto machines that precisely stitch the design using high-quality thread.

The result is a dimensional, textured design that adds perceived value to any garment. Remember that embroidery works best with simplified designs—we'll cover these limitations in detail later.

What Is Printing?

Printing is the transfer of ink directly onto garments to create vibrant, detailed designs. While several methods exist, we focus on two primary techniques: traditional screen printing and DTF (direct-to-film) transfers. Each serves different needs, so we select the best method based on your specific project requirements, considering factors like quantity, design complexity, and garment type.

T-shirts, hoodies, and bags are perfect candidates for printed decoration. Screen printing typically handles larger orders with simpler designs or spot-color logos, delivering incredible value and consistency at scale. DTF shines with smaller runs and complex artwork, offering photo-realistic detail and unlimited color options without minimum quantity requirements.

Screen printing process:

- Artwork is processed for simplification and color separation to create individual layers.

- Each color layer gets "burned" to a separate mesh screen and mounted on the press.

- The printer pushes ink through each screen onto the garment with a squeegee.

- The printed garments pass through a heat tunnel for final curing (drying).

DTF (Direct-to-Film) process:

- Artwork is sized and optimized for DTF printing.

- A DTF printer deposits the ink and adhesive layer onto special transfer film.

- The garment is loaded onto a heat press, and the printed DTF transfer is positioned.

- A single press of heat bonds the design, the film is peeled away, and a final press is applied.

Both printing methods produce durable, professional results that maintain their appearance through dozens of washes. The key difference lies in their ideal applications and the project requirements.

Pros & Cons

Each method has distinct advantages and limitations. Understanding the differences can help you make the right call for your specific project, whether you're prioritizing durability, design complexity, or cost-effectiveness.

Embroidery Pros

- Premium look: That dimensional, stitched finish instantly elevates any garment, making embroidered pieces feel more upscale and professional.

- Superior durability: Since designs are stitched into the fabric rather than printed on top, embroidered logos withstand years of wear and washing without degrading.

- Color retention: Thread colors maintain their vibrancy indefinitely, never fading or cracking like some printed designs can over time.

- Material versatility: The technique excels on structured and heavier materials, creating crisp, clean designs on everything from lightweight polos to heavy winter jackets.

Embroidery Cons

- Detail limitations: The physical constraints of thread and needle mean intricate details or photo-realistic images aren't possible with embroidery. Font choice is more limited.

- Color restrictions: While thread comes in many colors, achieving smooth gradients or color blends is challenging. Simpler designs with distinct color blocks work best.

- Higher cost: The digitization process and machine time make embroidery more expensive per piece, especially for larger designs or small quantity orders.

- Fabric sensitivity: The density of stitching can feel stiff or heavy on lightweight fabrics, potentially affecting garment comfort and drape.

Printing Pros

- Cost efficiency: Printing becomes incredibly economical at higher quantities, letting you create large or complex designs without breaking the budget.

- Color precision: Modern printing techniques offer exact Pantone color matching and specialty effects like metallic, glow-in-the-dark, or puff inks that make designs pop.

- Design freedom: Whether you're working with photographs, gradients, or intricate illustrations, printing (especially DTF) handles complex artwork with remarkable detail.

- Comfort factor: Printed designs integrate seamlessly with the garment, maintaining the fabric's natural drape and feel without adding weight.

Printing Cons

- Relative durability: While modern printing techniques are pretty durable, they still can't match embroidery's lifetime longevity through repeated washing and wear.

- Material restrictions: Screen printing works best on smooth, flat fabrics, while DTF expands these options, some specialty materials still aren't suitable for either method.

- Breathability impact: Large printed designs can affect a garment's natural drape and breathability, particularly on lightweight fabrics like performance wear or thin cotton tees.

- Casual appearance: While modern printing techniques look great, they may not convey the same level of sophistication as embroidery for formal business environments.

Best Use Cases

Embroidery Works Best For

- Structured items like hats, bags, and jackets where that dimensional stitched look shines.

- Corporate and professional environments that demand polished, upscale branding.

- Workwear and uniforms that face daily wear and frequent washing.

- Small, precise logos where you want that premium feel and maximum durability.

Printing Works Best For

- Casual garments like t-shirts, hoodies, and totes when you want maximum design flexibility.

- Large-scale promotional orders and event merchandise where cost-efficiency matters.

- Fashion-forward streetwear designs that incorporate complex artwork or photo elements.

- Any project requiring precise color matching, gradients, or highly detailed graphics.

Pricing

Embroidery pricing primarily depends on stitch count—essentially, how much thread it takes to create your design. Larger designs or those with intricate details require more stitches, increasing the cost. The digitization process can also factor into the initial setup costs, though this becomes negligible as the quantity increases.

The number of colors in your design influences printing costs, as each color requires a separate screen and setup. DTF pricing is more straightforward, based mainly on design size, since it can handle unlimited colors in one pass. Both methods become more cost-effective with larger quantities, though screen printing sees the most dramatic price breaks at higher volumes.

Our rolling volume pricing model means you don't have to hit specific tier breakpoints to save money; every additional piece ordered incrementally reduces the per-unit cost. This applies to both decoration methods, letting you maximize value whether you're ordering five or five hundred.

Turnaround

While printing typically offers faster turnaround times than embroidery, we've optimized both processes for speed. Our standard production takes 7-10 business days, but we can accommodate rush orders as quickly as 2-day delivery. Just keep in mind that complex designs or huge orders require additional time, regardless of the decoration method.

Making the Right Choice: Experience & Expertise Matter

Both embroidery and printing can create stunning custom apparel, but they shine in different situations. Embroidery delivers a premium, professional look perfect for corporate wear and branded uniforms, while printing offers unlimited creative possibilities for everything from team gear to promotional merchandise. The best choice ultimately depends on your specific needs: consider your design complexity, intended use, budget, and timeline.

With over two decades of in-house production experience, Rush Order Tees has mastered both embroidery and printing. Our state-of-the-art Tajima embroidery machines, advanced screen printing equipment, and DTF technology ensure consistent, high-quality results across every order. Our dedicated art team reviews each design, with free artwork optimization and expert guidance on production choices.

Not sure which direction to take? Upload your design and save it, then our project specialists can walk you through the options, weighing factors like quantity, garment type, design elements, and durability requirements. We back every order with our satisfaction guarantee, ensuring you get exactly what you need. Whether you're outfitting a small team or producing thousands of pieces, we'll help you find the perfect decoration solution.

About the Author

A graduate of the Multimedia program at the University of the Arts in Philadelphia, Imri Merritt is an industry veteran with over 20 years of graphic design and color separations experience in the screen printing industry.